Low Pressure Aluminum Castings: Complete Information

Your Comprehensive Guide to Aluminum Castings: Types, Processes, and Applications

Aluminum castings fulfill a crucial purpose in numerous industries, providing lightweight yet strong components. Various casting processes, such as sand and die casting, address specific production demands. Understanding these methods and their applications is essential for maximizing material use. As the demand for energy-efficient solutions grows, the importance of aluminum castings continues to increase. What factors should one consider when determining the right casting for a project?

What Are Aluminum Castings and Why Are They Important?

Aluminum castings are essential components in multiple industries, acting as the backbone of countless products and applications. These castings are formed by pouring molten aluminum into molds, permitting it to harden and take form. They are appreciated for their light weight, high strength, and corrosion resistance, making them perfect for the automotive, aerospace, and consumer electronics fields.

The value of aluminum castings stems from their ability to produce complex shapes and designs that would be challenging or unfeasible to achieve with other manufacturing techniques. Their versatility means they can be tailored to meet specific performance specifications, improving the overall functionality of products. Moreover, aluminum castings contribute to energy efficiency, as lighter components can result in reduced fuel consumption in vehicles and aircraft. Overall, the significance of aluminum castings is paramount, as they play a essential role in modern manufacturing and technology.

How Do You Make Aluminum Castings?

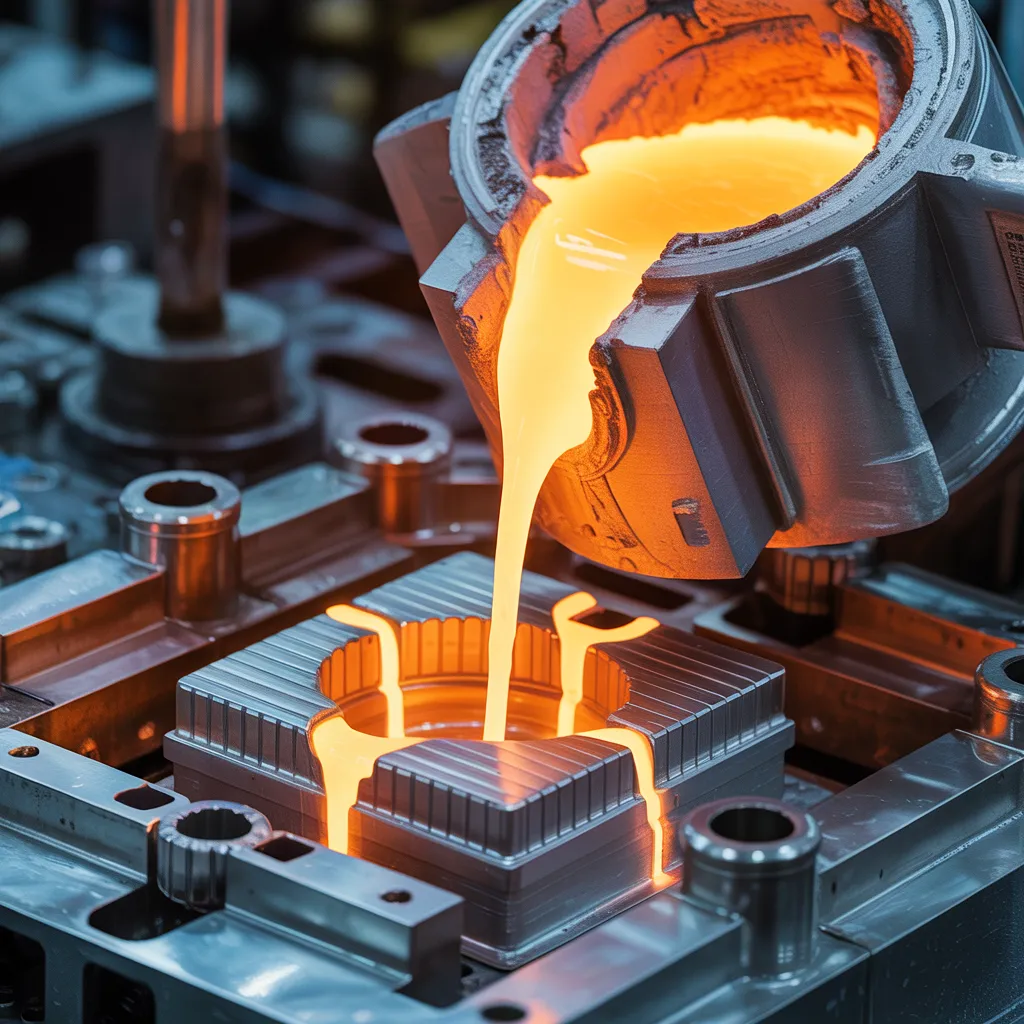

Aluminum casting creation encompasses several key steps that transform raw materials into precision-engineered components. To begin, high-quality aluminum materials are melted in a furnace, reaching temperatures around 1,200°F to 1,400°F. Once molten, the aluminum is often purified to remove impurities, ensuring excellent casting quality.

Afterward, the liquid aluminum is dispensed into a prepared mold, which can be fabricated from various materials based on the desired casting method. After the aluminum occupies the mold, it is permitted to cool and solidify, taking on the shape of the mold.

Following the cooling process, the casting is released from the mold and undergoes finishing processes, like machining, to reach the necessary tolerances and surface finishes. Finally, the cast component is inspected for quality assurance, guaranteeing it meets industry standards before being dispatched for use in numerous applications.

Popular Aluminum Casting Processes: Sand, Die, and Other Methods

Different processes are used within the aluminum casting industry to reach desired shapes and properties. Sand casting, recognized for its versatility and cost-effectiveness, and die casting, which provides high precision and efficiency, are among the most popular methods. These techniques each have their own advantages, which makes them suitable for diverse applications in manufacturing.

Sand Casting Procedure

While numerous casting approaches exist, sand casting continues to be one of the most commonly utilized processes in aluminum manufacturing thanks to its multi-purpose nature and cost-effectiveness. This technique requires creating a mold from sand, which is then injected with molten aluminum. The sand enables intricate designs and shapes, making it ideal for both large and small components. The process begins with the preparation of a sand mixture, followed by the formation of the mold around a pattern. Once the aluminum is dispensed and solidified, useful information the mold is broken to extract the casting. Sand casting is particularly advantageous for low to medium production runs, as it needs less initial investment in contrast to other techniques, while still yielding high-quality results.

Die Casting Techniques

Die casting techniques are a well-established method for producing aluminum components, especially when precise specifications and complex designs are necessary. This process consists of forcing molten aluminum into a mold cavity under high pressure, guaranteeing a exact replication of the mold's details. There are two primary types of die casting: hot chamber and cold chamber. Hot chamber die casting is ideal for low-melting-point alloys, while cold chamber is suited for higher melting-point materials. Both methods provide excellent dimensional accuracy and surface finish, making them appropriate for diverse applications, including automotive parts, consumer electronics, and industrial machinery. In summary, die casting techniques provide a trusted solution for manufacturers seeking quality and efficiency in aluminum component production.

Why Opt for Aluminum Castings?

When examining manufacturing options, numerous industries prefer aluminum castings due to their distinctive combination of strength, lightweight properties, and corrosion resistance. The versatility of aluminum makes it possible to be easily shaped into complex shapes, which makes it ideal for numerous applications. Furthermore, aluminum castings can be produced with high precision, which is vital for meeting demanding quality standards in today's manufacturing.

Furthermore, the thermal conductivity of aluminum elevates its performance in heat-related applications. Its capability to resist oxidation and maintain structural integrity over time makes it particularly appealing for outdoor and harsh environments. Additionally, aluminum castings offer outstanding recyclability, enabling sustainable manufacturing practices. The overall cost-effectiveness, along with the reduced weight of aluminum components, generates lower transportation costs and energy savings in end products. These advantages position aluminum castings as a preferred choice across multiple sectors, including automotive, aerospace, and consumer goods.

Where Can Aluminum Castings Be Found?

Aluminum castings are extensively applied across multiple industrial sectors due to their favorable attributes. In the automotive sector, they are frequently utilized for engine blocks, transmission cases, and structural components, resulting in weight reduction and increased fuel efficiency. The aerospace industry utilizes aluminum castings for aircraft components, where the strength-to-weight ratio is critical.

Additionally, the electronics industry uses aluminum castings for housings and heat sinks, benefiting from their superior thermal conductivity. In the construction sector, they are utilized for architectural elements and structural supports, enhancing durability and aesthetics.

Furthermore, the marine industry makes use of aluminum castings for boat components, providing resistance to corrosion. Consumer products, like cookware and appliances, also employ aluminum castings for their lightweight and efficient heat distribution. On the whole, aluminum castings are integral to diverse applications, highlighting their versatility and utility in modern manufacturing.

Selecting the Perfect Aluminum Casting for Your Project

What's the process for determining the most optimal aluminum casting for individual applications? The evaluation process commences by evaluating the application's requirements, including physical properties, thermal resistance, and weight requirements. Understanding the operating environment is necessary; for instance, exposure to corrosive agents may require a specialized alloy.

Subsequently, the manufacturing process should be evaluated. Sand casting is well-suited for intricate geometries, while die casting offers high precision for large-scale manufacturing. Additionally, cost considerations and lead times can impact the decision between these methods.

The planned application also plays a crucial part; automotive components may require different properties than aerospace parts. Consulting with a casting expert can provide valuable insights into the best options available. Ultimately, a thorough assessment of these factors guarantees the selection of an aluminum casting that meets both performance and economic needs.

FAQ

What Are the Environmental Consequences of Aluminum Casting Production?

The process of aluminum casting production generates noteworthy environmental impacts, including waste generation, greenhouse gas emissions, and energy consumption. Moreover, the extraction of bauxite for aluminum production may result in habitat destruction and soil degradation. Sustainable practices are essential.

What Are the Differences Between Aluminum and Steel Castings?

Aluminum castings tend to be lighter in weight, corrosion-resistant, and deliver enhanced thermal conductivity when compared to steel castings. Nonetheless, castings made from steel are generally stronger and offer greater durability, making them preferable in applications requiring high strength and load-bearing capabilities.

Is It Possible to Recycle Aluminum Castings?

Aluminum castings can undergo efficient recycling processes. The recycling procedure sustains material properties, cutting down on energy needs and environmental consequences. Such characteristics position aluminum castings as an eco-friendly option across multiple sectors, supporting circular economic principles.

What Are Frequent Defects in Aluminum Castings?

Common defects in aluminum castings include porosity, shrinkage, inclusions, along with surface imperfections. These issues can arise from improper melting practices, incorrect mold design, or inconsistent cooling rates, affecting the performance and integrity of the final product.

What's the Best Way to Maintain Aluminum Cast Products?

To care for aluminum cast products, one should regularly clean them with a mild detergent, steer clear of abrasive materials, monitor for corrosion, apply coating protection, and store them in a temperature-controlled, dry environment to avoid damage.